Views: 222 Author: Tina Publish Time: 2024-12-06 Origin: Site

Content Menu

● Understanding LCD Counter Modules

>> Key Components of an LCD Counter Module

● How LCD Counter Modules Work

● Applications of LCD Counter Modules

● Types of LCD Counter Modules

● Integrating LCD Counter Modules with Arduino

>> Steps to Connect an LCD Counter Module to Arduino:

● Advanced Features of Modern LCD Counter Modules

● Maintaining and Troubleshooting LCD Counter Modules

>> Common Issues and Solutions:

● Future Trends in LCD Counter Module Technology

● Frequently Asked Questions (FAQ)

>> 1. What is the typical lifespan of an LCD counter module?

>> 2. Can LCD counter modules be used in outdoor environments?

>> 3. How accurate are LCD counter modules?

>> 4. Can LCD counter modules be integrated with other systems?

>> 5. Are there any alternatives to LCD counter modules?

An LCD counter module is a compact electronic device that combines a liquid crystal display (LCD) with counting circuitry. These modules are designed to count and display numerical values, making them ideal for a wide range of applications where real-time counting and visual feedback are required.

1. LCD Display: The heart of the module, typically featuring multiple digits to show the count.

2. Microcontroller: Manages the counting logic and display control.

3. Input Interface: Allows the module to receive signals for counting.

4. Power Supply: Provides the necessary voltage to operate the module.

LCD counter modules operate on a simple yet effective principle. When an input signal is received, the microcontroller processes it and updates the count accordingly. This count is then displayed on the LCD screen in real-time.

1. Signal Detection: The module detects an input signal, often from a sensor or switch.

2. Signal Processing: The microcontroller interprets the signal and determines if it should increment or decrement the count.

3. Count Update: The internal count value is modified based on the processed signal.

4. Display Refresh: The LCD is updated to show the new count value.

This process happens rapidly, giving the appearance of instantaneous counting and display.

LCD counter modules find applications in various fields due to their versatility and ease of use. Some common applications include:

- Industrial Production Lines: Counting manufactured items or tracking production cycles.

- Retail Stores: Monitoring customer traffic or inventory management.

- Fitness Equipment: Tracking repetitions or distance traveled.

- Scientific Experiments: Recording occurrences of specific events.

- Security Systems: Counting entries and exits in restricted areas.

There are several types of LCD counter modules available, each designed for specific needs:

These modules only count upwards, incrementing the displayed value with each input signal. They are ideal for applications where total accumulation is required.

More versatile than up counters, these modules can count both up and down. They are perfect for tracking bidirectional movement or inventory that can increase and decrease.

These advanced modules allow users to set a target count. When the count reaches the preset value, the module can trigger an action, such as sounding an alarm or activating a relay.

The most flexible type, multifunction counters can perform various counting operations and often include additional features like timers or rate meters.

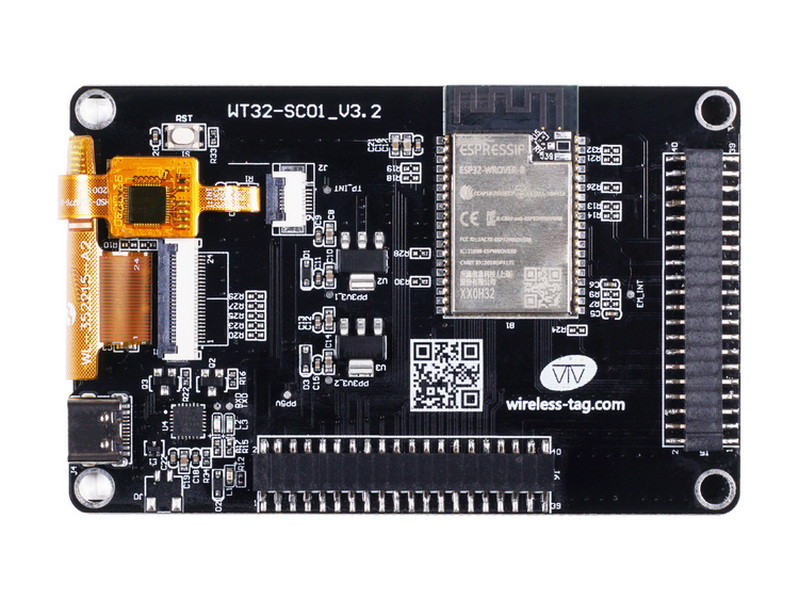

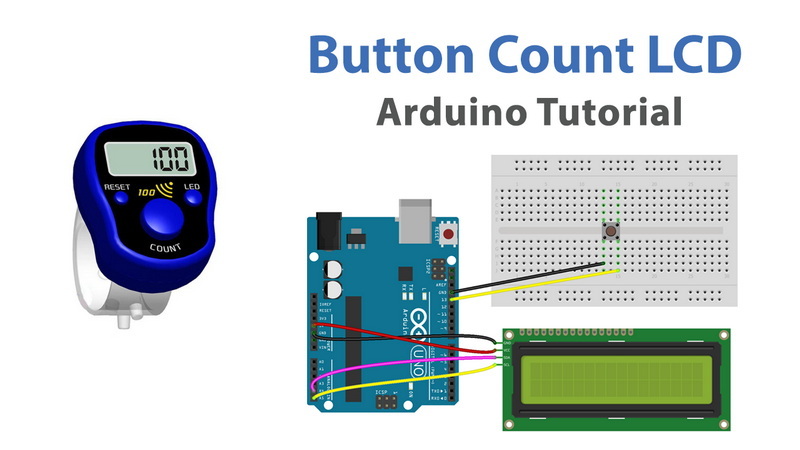

For hobbyists and DIY enthusiasts, integrating an LCD counter module with an Arduino board opens up a world of possibilities. This combination allows for custom programming and enhanced functionality.

1. Wiring: Connect the LCD module to the Arduino using the appropriate pins.

2. Library Installation: Install the necessary LCD library in the Arduino IDE.

3. Programming: Write a sketch to control the LCD and implement the counting logic.

4. Testing: Upload the sketch and test the functionality.

As technology advances, LCD counter modules are becoming more sophisticated, offering features that enhance their functionality and user experience:

Many modern LCD counter modules come with backlit displays, making them easy to read in low-light conditions. This feature is particularly useful in industrial settings or outdoor applications.

Advanced modules often offer various display modes, allowing users to switch between different types of information, such as current count, maximum count, or count rate.

Some high-end LCD counter modules include data logging capabilities, storing count data over time for later analysis or reporting.

With the rise of IoT, some LCD counter modules now offer wireless connectivity options, allowing for remote monitoring and control.

To ensure the longevity and accuracy of LCD counter modules, proper maintenance and troubleshooting are essential:

1. Regular Cleaning: Keep the LCD screen and input interfaces clean and free from debris.

2. Power Management: Ensure stable power supply to prevent erratic behavior.

3. Environmental Protection: Shield the module from extreme temperatures and humidity.

1. Faded Display: Adjust contrast or replace backlighting.

2. Inaccurate Counting: Check input signal integrity and recalibrate if necessary.

3. Unresponsive Buttons: Clean button contacts or replace if worn out.

The future of LCD counter modules looks promising, with several emerging trends:

1. Touchscreen Interfaces: Replacing physical buttons with touch-sensitive displays for improved user interaction.

2. Energy Efficiency: Development of ultra-low-power modules for battery-operated and IoT applications.

3. AI Integration: Incorporating artificial intelligence for predictive maintenance and advanced data analysis.

4. Flexible Displays: Research into flexible LCD technology for curved or non-standard form factors.

LCD counter modules are versatile and essential components in many electronic systems, offering reliable counting and display functionality. From simple up counters to sophisticated multifunction devices, these modules continue to evolve, meeting the diverse needs of various industries and applications. As technology advances, we can expect to see even more innovative features and applications for LCD counter modules, further cementing their place in the world of electronics and data management.

The lifespan of an LCD counter module can vary depending on usage and environmental conditions. On average, a well-maintained module can last 5-10 years or more. Factors such as operating temperature, humidity, and frequency of use can affect its longevity. Regular maintenance and proper usage can significantly extend the life of the module.

Yes, LCD counter modules can be used outdoors, but special considerations are necessary. Look for modules with IP-rated enclosures to protect against dust and moisture. Additionally, choose modules with wide operating temperature ranges and high-contrast displays that remain visible in bright sunlight. Some manufacturers offer ruggedized versions specifically designed for outdoor use.

The accuracy of LCD counter modules is generally very high, especially for digital input signals. Most modules have an accuracy of ±1 count. However, factors like input signal quality, power supply stability, and environmental conditions can affect accuracy. For applications requiring extreme precision, it's important to choose a high-quality module and ensure proper installation and calibration.

Absolutely. Many LCD counter modules come with various output options such as serial communication (RS232, RS485), USB, or even wireless interfaces. This allows them to be easily integrated with PLCs, computers, or other control systems. Some advanced modules also offer Modbus or other industrial communication protocols for seamless integration into larger automation systems.

While LCD counter modules are popular, there are alternatives depending on the specific application:

- LED Displays: Offer high visibility but typically consume more power.

- OLED Displays: Provide better contrast and viewing angles but can be more expensive.

- E-ink Displays: Ideal for low-power applications but have slower refresh rates.

- Digital Panel Meters: Often used in industrial settings for various measurements including counting.

The choice depends on factors like power consumption, visibility requirements, cost, and integration needs.

This comprehensive article answers the question "Can I Upgrade My E-Bike LCD Display Easily?" by exploring display types, compatibility, practical upgrade steps, troubleshooting, and maintenance tips. Boost your riding experience and get the most from your LCD display e-bike with the best current advice, illustrations, and video guidance.

This comprehensive guide explores the troubleshooting and repair of backpack LCD display issues, covering blank screens, flickers, garbled text, address conflicts, and more. It offers stepwise solutions and practical videos to help users swiftly restore functionality in their hardware projects.

Discover why the Sharp memory LCD display outperforms traditional LCDs with lower power use, unmatched sunlight readability, robust reliability, and a straightforward interface. Learn about its technology, applications, pros and cons, integration tips, and get answers to common engineering questions.

OLED displays, though admired for their visuals, may cause digital eye strain or "OLED screen eye tire" during extended use because of blue light, potential PWM flicker, and intense color/contrast. By using optimal settings and healthy habits, users can safely enjoy OLED with minimal discomfort.

Does displaying a white screen on an LG OLED TV fix persistent burn-in? The answer is no: true burn-in results from irreversible pixel wear and chemical aging. The best practice is to use preventive features, moderate settings, and varied content to safeguard screen health. For severe cases, panel replacement is the only cure.

An in-depth guide to the LCD display bezel: its definition, history, materials, structure, and growing role in display design. Explores bezel importance, types, aesthetic trends, maintenance, and innovation, offering expert insights—including an expanded FAQ and practical visuals—to help users understand its unique place in technology.

This article provides a complete, practical guide to diagnosing and fixing non-responsive SPI LCD displays using methods including hardware validation, logic level correction, library configuration, and advanced diagnostic tools. Perfect for hobbyists and engineers alike.

LCD display liquid coolers deliver top-tier performance with visually stunning customizable LCD panels that display system data and artwork. They suit enthusiasts and streamers aiming for unique builds but may be unnecessary for budget or basic systems. The price premium is justified by advanced hardware, software, and customization features.

Black bars on an OLED screen do not cause burn-in as those pixels are switched off. Only with excessive, repetitive content does minor uneven aging become possible. Varying viewing habits and enabling panel maintenance prevents problems in daily use.

OLED TVs provide spectacular picture quality but rely heavily on the quality of the video input. Most cable broadcasts are limited to lower resolutions and compressed formats, so an OLED screen connected to a regular cable box will look better than older TVs but may not realize its full potential. Upgrading cable boxes and utilizing streaming services can unlock the best OLED experience.

OLED screen burn-in remains one of the key challenges inherent in this display technology. While no universal fix exists for permanent burn-in, a blend of app-based tools, manufacturer features, and maintenance practices can help reduce appearance and delay onset. Proper prevention strategies and use of built-in pixel shift and refresher tools offer the best chances of avoiding this issue.

This article comprehensively explores will OLED screen burn in over time by explaining the science of OLED displays, causes and types of burn in, manufacturer solutions, prevention tips, and real-world user experiences. Burn in risk does exist, but modern panels and user habits greatly reduce its likelihood, making OLED an excellent and long-lasting display choice.

This article provides an in-depth guide to selecting the best LCD display driver IC for various applications, covering driver types, key features, leading manufacturers, integration tips, and practical examples. It includes diagrams and videos to help engineers and hobbyists make informed decisions about LCD display driver selection.

Dead pixels are a common type of LCD display defect, caused by manufacturing faults, physical damage, or environmental factors. While stuck pixels may be fixable, dead pixels are usually permanent. Proper care and understanding can help prevent and address these issues.

This comprehensive guide explains every symbol and function found on e-bike LCD displays, using clear explanations and practical tips. Learn to interpret battery, speed, PAS, error codes, and customize settings using your e-bike LCD display manual for a safer, smarter ride.

This comprehensive guide explains how to set an LCD display clock, covering everything from hardware setup and wiring to coding, troubleshooting, and creative customization. With detailed instructions and practical tips, you'll learn to confidently build and personalize your own LCD display clock for any setting.

This article explores whether OLED laptop screens are prone to burn-in, examining the science, real-world evidence, prevention methods, and lifespan. It provides practical advice and answers common questions to help users make informed decisions about OLED technology.

Displaying a black screen on an OLED TV will not cause burn-in, as the pixels are turned off and not subject to wear. Burn-in is caused by static, bright images over time. With proper care and built-in features, OLED TVs are reliable and offer exceptional picture quality.

This article explores the causes of OLED screen burn-in, the science behind it, and effective prevention strategies. It covers signs, effects, and potential fixes, with practical tips to prolong your OLED display's lifespan and answers to common questions about burn-in.

OLED screens deliver unmatched image quality, with perfect blacks, vivid colors, and ultra-fast response times. Despite higher costs and some risk of burn-in, their advantages make them the top choice for premium displays in TVs, smartphones, and monitors.