- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 222 Author: Tina Publish Time: 2025-01-19 Origin: Site

Content Menu

● Understanding the Components

● Adjusting Contrast Without a Potentiometer

● Troubleshooting Common Issues

● Additional Techniques for Contrast Control

● Practical Applications of LCD with Arduino

● Detailed Overview of LCD Technology

● Benefits of Using an LCD with Arduino

● Advanced Techniques for Enhanced Functionality

● FAQs

>> 1. Can I use any other digital pin instead of Pin 6?

>> 2. What if my LCD still does not work?

>> 3. Is it possible to use multiple LCDs with one Arduino?

>> 4. How can I change what is displayed on my LCD?

>> 5. What if I want more than two lines on my display?

Interfacing an LCD display with an Arduino can be a rewarding project, especially for beginners looking to expand their knowledge of electronics and programming. While many tutorials suggest using a potentiometer to control the contrast of the LCD, it is entirely possible to connect an LCD display to an Arduino without one. This article will guide you through the process, providing detailed instructions, circuit diagrams, and explanations.

Before diving into the connections and coding, let's briefly discuss the components required for this project:

Components Required:

- Arduino Uno: The microcontroller board that will control the LCD.

- 16x2 LCD Display: A common alphanumeric display that can show 16 characters per line and has two lines.

- Jumper Wires: Used for making connections between the Arduino and the LCD.

- Breadboard: Optional but helpful for organizing your circuit.

- Arduino IDE: The software used to write and upload code to the Arduino.

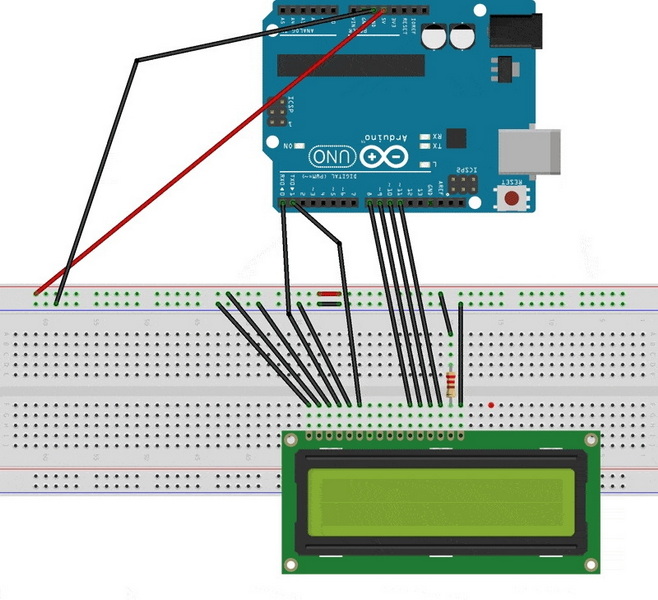

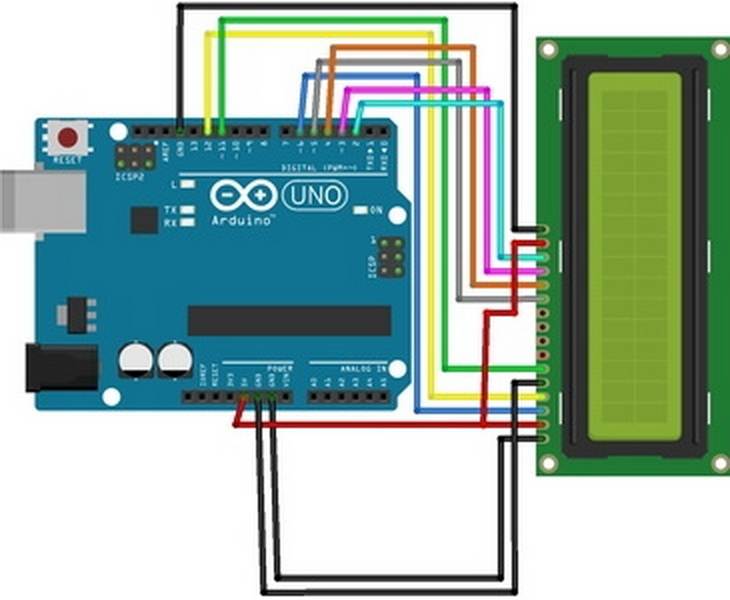

In this setup:

- Pin 1 (VSS): Connect to GND

- Pin 2 (VDD): Connect to +5V

- Pin 3 (V0): Connect to a PWM-capable digital pin (e.g., Pin 6)

- Pin 4 (RS): Connect to Pin 12

- Pin 5 (RW): Connect to GND

- Pin 6 (E): Connect to Pin 11

- Pins D4-D7: Connect Pins D4-D7 of the LCD to Pins 5, 4, 3, and 2 of the Arduino respectively.

In this configuration, instead of using a potentiometer for contrast adjustment, we will use PWM (Pulse Width Modulation) from one of the digital pins. This allows us to control the voltage applied to the contrast pin effectively.

To achieve this, you can set a specific PWM value in your code that corresponds to your desired contrast level. Typically, values between 60 and 120 work best for most displays. This method eliminates the need for additional components while still allowing you to adjust contrast as needed.

Once you have uploaded your code to the Arduino using the Arduino IDE:

1. Ensure all connections are secure.

2. Power on your Arduino.

3. You should see "Hello World!" displayed on your LCD.

If you do not see any text or if it appears as black boxes, try adjusting the value in your PWM setting until you achieve a readable contrast.

- No Display: Check all connections; ensure power is supplied correctly.

- Black Boxes Instead of Characters: Adjust PWM value in your code.

- Flickering Display: Ensure you are using a stable power supply and consider adding a capacitor across VCC and GND for smoothing.

If you're looking for more ways to control contrast without a potentiometer, consider these alternatives:

You can use fixed resistors instead of a potentiometer. For example, connecting a resistor between V0 and GND can provide sufficient contrast without needing variable adjustment. Common resistor values range from 1kΩ to 5kΩ depending on your specific LCD model.

Another approach is using two resistors in a voltage divider configuration connected between VCC and GND with V0 connected at their junction. This method creates a stable voltage level that can be suitable for controlling contrast without any additional adjustments.

If flickering occurs when using PWM directly on V0, consider employing a low-pass filter using a capacitor in conjunction with a resistor. This setup smooths out the PWM signal into a more stable DC voltage that can be fed into V0, thus reducing flicker while maintaining control over contrast.

Interfacing an LCD with an Arduino opens up numerous practical applications:

- Data Display: Use it for displaying sensor data such as temperature, humidity, or distance.

- User Interfaces: Create simple user interfaces for projects like home automation systems or robotics.

- Timers and Clocks: Build timers or clocks that display time or countdowns on the screen.

These applications demonstrate how versatile an LCD can be when combined with an Arduino.

Understanding how LCDs work is crucial before diving into interfacing them with microcontrollers like Arduino.

LCD stands for Liquid Crystal Display. It utilizes liquid crystals that align when exposed to electric fields allowing them to modulate light passing through them. This technology is widely used in various devices due to its low power consumption compared to traditional LED displays.

An LCD consists of several layers:

1. Backlight Layer: Provides illumination from behind.

2. Polarizers: Control light passage through liquid crystals.

3. Liquid Crystal Layer: Changes light properties based on applied voltage.

4. Glass Substrates: Protects internal components while allowing visibility.

When voltage is applied across specific segments of liquid crystals, they twist or align in such a way that either allows light through or blocks it—this creates visible characters or images on the screen.

Several types of LCDs exist based on their construction and application:

- Character Displays: Such as the popular 16x2 format used in this tutorial.

- Graphic Displays: Capable of displaying complex images and graphics.

- Segmented Displays: Often found in calculators and clocks showing numerical values only.

Each type has its own interfacing requirements but shares similar principles regarding voltage control for visibility adjustments.

Integrating an LCD with an Arduino opens up numerous benefits:

LCDs provide clear visual feedback which makes them ideal for user interfaces where users need immediate information about system status or settings.

Compared to other display technologies like CRTs or even some LED displays, LCDs consume significantly less power making them suitable for battery-operated devices.

From simple projects like displaying temperature readings from sensors to complex systems such as home automation dashboards—LCDs are adaptable across various domains.

Once comfortable with basic interfacing techniques, consider these advanced methods:

The LiquidCrystal library simplifies interaction with character-based displays by providing functions for text manipulation and cursor positioning—making programming more intuitive.

Many character-based displays allow users to define custom characters beyond standard ASCII sets—this feature can be useful for creating unique symbols relevant to specific applications such as icons representing system states or alerts.

For projects requiring more information at once, consider using graphic displays capable of showing multiple lines of text or even images—these often require more complex libraries but offer greater flexibility in presentation style.

Connecting an LCD display to an Arduino without a potentiometer is not only feasible but also opens up numerous possibilities for projects ranging from simple data displays to complex user interfaces. With various methods available for controlling contrast effectively through PWM signals or fixed resistors, enthusiasts at all levels can engage in exciting electronics projects without needing extensive component inventories.

By understanding both basic principles and advanced techniques related to interfacing these displays with microcontrollers like Arduino, creators can push their projects further while maintaining simplicity in design—ultimately leading towards innovative solutions across diverse fields such as robotics, automation systems, and educational tools alike!

Yes, you can use any PWM-capable digital pin on your Arduino. Just ensure you update your code accordingly.

Double-check all wiring connections against your circuit diagram. Ensure that your Arduino is functioning properly by testing it with other simple projects.

Yes! However, you will need to manage pin assignments carefully and may require additional libraries or multiplexing techniques depending on how many displays you plan to use.

You can modify the `lcd.print()` commands in your code within the `setup()` or `loop()` functions as needed.

You would need an LCD that supports more than two lines or consider using multiple displays in conjunction with your Arduino.

[1] https://www.youtube.com/watch?v=IM3d0dlAOJk

[2] https://github.com/hrsajjad844/LCD-Display-without-Potentiometer-and-Resistor

[3] https://electronics.stackexchange.com/questions/2574/arduino-hooking-up-lcd-without-pot

[4] https://www.instructables.com/Arduino-Interfacing-With-LCD-Without-Potentiometer/

[5] https://projecthub.arduino.cc/TechWithZan/arduino-nano-lcd-stopwatch-without-potentiometer-d461c7

[6] https://arduino.stackexchange.com/questions/96944/lcd-display-connection-without-a-resistor

[7] https://highvoltages.co/tutorial/arduino-tutorial/arduino-lcd-interfacing-without-potentiometer/

[8] https://www.hackster.io/captain_nemo01/lcd-without-potentiometer-f1a7ef

[9] https://robosans.com/learn/embedded/arduino/16x2-lcd-interfacing-with-arduino/

[10] https://www.hackster.io/hrsajjad844/lcd-display-without-potentiometer-and-resistor-0d1357

[11] https://forum.arduino.cc/t/i-need-to-connect-a-lcd-to-an-arduino-without-potentiometer/148261

[12] https://projecthub.arduino.cc/captain_nemo01/lcd-without-potentiometer-35cb96

[13] https://highvoltages.co/tutorial/arduino-lcd-interfacing-without-potentiometer/

[14] https://www.youtube.com/watch?v=zzGWcZ2E5CY

This comprehensive article answers the question "Can I Upgrade My E-Bike LCD Display Easily?" by exploring display types, compatibility, practical upgrade steps, troubleshooting, and maintenance tips. Boost your riding experience and get the most from your LCD display e-bike with the best current advice, illustrations, and video guidance.

This comprehensive guide explores the troubleshooting and repair of backpack LCD display issues, covering blank screens, flickers, garbled text, address conflicts, and more. It offers stepwise solutions and practical videos to help users swiftly restore functionality in their hardware projects.

Discover why the Sharp memory LCD display outperforms traditional LCDs with lower power use, unmatched sunlight readability, robust reliability, and a straightforward interface. Learn about its technology, applications, pros and cons, integration tips, and get answers to common engineering questions.

OLED displays, though admired for their visuals, may cause digital eye strain or "OLED screen eye tire" during extended use because of blue light, potential PWM flicker, and intense color/contrast. By using optimal settings and healthy habits, users can safely enjoy OLED with minimal discomfort.

Does displaying a white screen on an LG OLED TV fix persistent burn-in? The answer is no: true burn-in results from irreversible pixel wear and chemical aging. The best practice is to use preventive features, moderate settings, and varied content to safeguard screen health. For severe cases, panel replacement is the only cure.

An in-depth guide to the LCD display bezel: its definition, history, materials, structure, and growing role in display design. Explores bezel importance, types, aesthetic trends, maintenance, and innovation, offering expert insights—including an expanded FAQ and practical visuals—to help users understand its unique place in technology.

This article provides a complete, practical guide to diagnosing and fixing non-responsive SPI LCD displays using methods including hardware validation, logic level correction, library configuration, and advanced diagnostic tools. Perfect for hobbyists and engineers alike.

LCD display liquid coolers deliver top-tier performance with visually stunning customizable LCD panels that display system data and artwork. They suit enthusiasts and streamers aiming for unique builds but may be unnecessary for budget or basic systems. The price premium is justified by advanced hardware, software, and customization features.

Black bars on an OLED screen do not cause burn-in as those pixels are switched off. Only with excessive, repetitive content does minor uneven aging become possible. Varying viewing habits and enabling panel maintenance prevents problems in daily use.

OLED TVs provide spectacular picture quality but rely heavily on the quality of the video input. Most cable broadcasts are limited to lower resolutions and compressed formats, so an OLED screen connected to a regular cable box will look better than older TVs but may not realize its full potential. Upgrading cable boxes and utilizing streaming services can unlock the best OLED experience.

OLED screen burn-in remains one of the key challenges inherent in this display technology. While no universal fix exists for permanent burn-in, a blend of app-based tools, manufacturer features, and maintenance practices can help reduce appearance and delay onset. Proper prevention strategies and use of built-in pixel shift and refresher tools offer the best chances of avoiding this issue.

This article comprehensively explores will OLED screen burn in over time by explaining the science of OLED displays, causes and types of burn in, manufacturer solutions, prevention tips, and real-world user experiences. Burn in risk does exist, but modern panels and user habits greatly reduce its likelihood, making OLED an excellent and long-lasting display choice.

This article provides an in-depth guide to selecting the best LCD display driver IC for various applications, covering driver types, key features, leading manufacturers, integration tips, and practical examples. It includes diagrams and videos to help engineers and hobbyists make informed decisions about LCD display driver selection.

Dead pixels are a common type of LCD display defect, caused by manufacturing faults, physical damage, or environmental factors. While stuck pixels may be fixable, dead pixels are usually permanent. Proper care and understanding can help prevent and address these issues.

This comprehensive guide explains every symbol and function found on e-bike LCD displays, using clear explanations and practical tips. Learn to interpret battery, speed, PAS, error codes, and customize settings using your e-bike LCD display manual for a safer, smarter ride.

This comprehensive guide explains how to set an LCD display clock, covering everything from hardware setup and wiring to coding, troubleshooting, and creative customization. With detailed instructions and practical tips, you'll learn to confidently build and personalize your own LCD display clock for any setting.

This article explores whether OLED laptop screens are prone to burn-in, examining the science, real-world evidence, prevention methods, and lifespan. It provides practical advice and answers common questions to help users make informed decisions about OLED technology.

Displaying a black screen on an OLED TV will not cause burn-in, as the pixels are turned off and not subject to wear. Burn-in is caused by static, bright images over time. With proper care and built-in features, OLED TVs are reliable and offer exceptional picture quality.

This article explores the causes of OLED screen burn-in, the science behind it, and effective prevention strategies. It covers signs, effects, and potential fixes, with practical tips to prolong your OLED display's lifespan and answers to common questions about burn-in.

OLED screens deliver unmatched image quality, with perfect blacks, vivid colors, and ultra-fast response times. Despite higher costs and some risk of burn-in, their advantages make them the top choice for premium displays in TVs, smartphones, and monitors.